Bradford, Pa. – American Refining Group (ARG) is pleased to showcase our Kendex® 0834, Heavy Resin as an exceptional product offering unrivaled performance in industrial lubricant applications and beyond. A paraffinic resin, Kendex 0834 offers enhanced protection, reliability, and versatility in a broad range of uses due to its high viscosity and shear stability.

“Our resin is unlike others because of the type of crude oil we refine,” states Mike Kozminski, Vice President of Research and Development at ARG. Originating from specially selected Penn Grade crude oil, Kendex 0834 is well-known for exceptional quality. In fact, Kendex 0834 is a high viscosity paraffinic resin that continues to be refined from light sweet paraffinic crude oils that do not contain an appreciable level of asphaltenes. As a high-viscosity Newtonian fluid it provides superior film thickness and will not undergo permanent shear loss in boundary lubrication regimes and therefore maintains constant viscosity across varying shear rates.

“Because it is naturally paraffinic, the Kendex 0834 is an excellent viscosity builder in lubricant formulations such as Industrial Gear Oils, open gear compounds, wire rope lubricants, greases, and other industrial lubricant applications” notes Kozminski.

When used in a variety of quench oil applications including fast and medium quench oils, the Kendex 0834 ingredient serves to accelerate the vapor to boiling phase in the quenching process. In addition to lubricant and grease applications, it also provides some unique attributes in roofing asphalt with improved ductility, durability, and weatherability. The paraffinic nature of the Kendex 0834 also serves as a moisture barrier ingredient in products formulated for underground use and other barrier-type functions. It passes Method IP 346 testing for dermal carcinogenicity of base oils and is therefore non-carcinogenic.

Kendex 0834 has a long and proven performance history over many generations. Over the course of the long history of Kendex 0834 it has been referred to by many different names including: Penn (Pennsylvania) Resins, 2600 SUS Resin, and Heavy Resins.

Available in 55-gallon steel drums, along with bulk shipments in trucks, railcars and ISOtainers, it is REACH registered for imports to Europe, and available for purchase worldwide. ARG’s top-notch sales and customer service teams can easily support shipment both domestically and internationally.

For more information go to https://www.amref.com/landing-page/arg-kendex-0834/.

“If you think you’re too small to make a difference, you’ve never spent the night with a mosquito.”

BRADFORD, Pa. – Halloran Philanthropies has given a gift of $700,000 to the University of Pittsburgh at Bradford to be used to complete the construction of and purchase specialized equipment for the new George B. Duke Engineering and Information Technologies Building.

The gift will be used in part to equip the fluid dynamics lab and makerspace, two of several unique and innovative spaces in the new building, with several pieces, including a wind tunnel and 3D printing and scanning for rapid prototyping.

“When our father Harry Halloran Jr. passed nearly one year ago, he left a rich legacy of philanthropy, vision and entrepreneurship,” said Brian Halloran, executive director of Halloran Philanthropies and one of Harry’s four sons.

Neil Halloran added, “Our father was a businessperson, a philanthropist, a big thinker and a kind soul. He pursued so many interests, launched so many ventures and impacted so many lives. Harry was always enthusiastically supportive of efforts to promote economic growth in Bradford, especially when it involved entrepreneurship and technological innovation.”

In that spirit, Halloran Philanthropies gears its giving toward business tools and educational programs to empower individuals who can make a difference.

These new labs, as well as the rest of the building, will open to students when the spring semester starts on Jan. 9. The Duke Building will be home to the university’s two new engineering technology majors –– mechanical engineering technology and energy engineering technology –– as well as the existing programs of computer information systems and technology, energy science and technology, and information systems.

“We are deeply grateful to the Halloran family for their generosity and continuing support of our programs,” said Rick Esch, Pitt-Bradford’s president. “Halloran Philanthropies, which was founded by Harry Halloran Jr., has been a longtime and generous supporter of our campus. The Hallorans specifically chose to support these two spaces because Harry was actively involved in the renewable energy field and was passionate about the kinds of innovation that will occur in these two areas.”

The fluid dynamics lab and makerspace will be complementary spaces, allowing students to take their understanding of engineering principles and apply them throughout the process –– from theory, simulation, design, prototype, development, manufacturing, and in situ validation. For example, students studying the optimization of steam turbine impeller design will be able to generate 3D printed prototypes of the design, verify simulation results in a wind tunnel, then manufacture a scaled model and validate the efficiency of the new design by implementing it into an actual Rankine cycle steam turbine power generation model equipped with data acquisition hardware.

Additionally, the makerspace will provide valuable opportunities to the community by filling a vital gap in resources for start-up manufacturers as well as established industries looking to enhance capabilities within product research and development. This community benefit also will enhance our students’ exposure to entrepreneurial endeavors and provide more opportunities to work with industry on projects, internships, and co-ops.

“Halloran Philanthropies uses a proven, multi-pronged approach that has boosted economies across the U.S. by putting in place what is needed for entrepreneurs to put their ideas to work locally,” Brian Halloran said.

He added, “Pitt-Bradford is one of several critical components in building a flourishing entrepreneurial ecosystem in Bradford and McKean County. A successful ecosystem must combine entrepreneurship education, community engagement, investment opportunity, local institutional support and access to broader networks.”

Jon Giberson, president and chief operating officer at American Refining Group Inc. (ARG), said, “ARG’s Bradford refinery marked 25 years of ownership by the Halloran family this year and these principles Brian and Neil have identified are the foundation for how we approach business and corporate citizenship.

“This grant strengthens an already well-established and mutually beneficial partnership between Pitt-Bradford and our area’s businesses and industries, not just ARG,” Giberson added.

In addition to the makerspace and fluids dynamics lab, the new building will house several other innovative and specialized areas:

- A circuit lab with bench space for soldering, function generators, analog and digital microcontrollers, spectrum analyzer, and oscilloscopes.

- A measurements lab where students will be able to work with sensors and automation in a space containing programmable logic controllers, wireless sensing hardware, ultrasonic flaw detectors, and more.

- A machine shop with computer-controlled plasma cutter, CNC milling machines and lathes, variable speed drill presses, band saws, machine presses, disc and belt grinders, welders, and rapid prototype machines.

- A strength and materials lab, where students can test, measure, and destroy their creations by pulling, pushing, and hitting them with a compression/tension tester and a dynamic fatigue tester as well as testers for impact, hardness, and torque.

- An expanded Systems, Networks and Projects Lab –– known as a SNAP Lab –– to enable students to practice setting up small computer and data operation centers.

- A FLEX Lab to give students the space they need to gather data, perform analyses, and creative virtual and scaled prototypes for new products and services.

- A virtual reality lab equipped with a presentation platform and a huge screen on which students can present projects as well as an 18-foot ceiling to allow for hanging sensors and cameras.

The building also will include several areas where students from different academic disciplines can collaborate, challenge and inspire each other, and turn their ideas to reality, including a two-story atrium, study rooms and a project lab.

A dedication for the Duke Building will be held March 31, which will give residents the opportunity to tour the new building and see the unique labs where students are working on innovative projects.

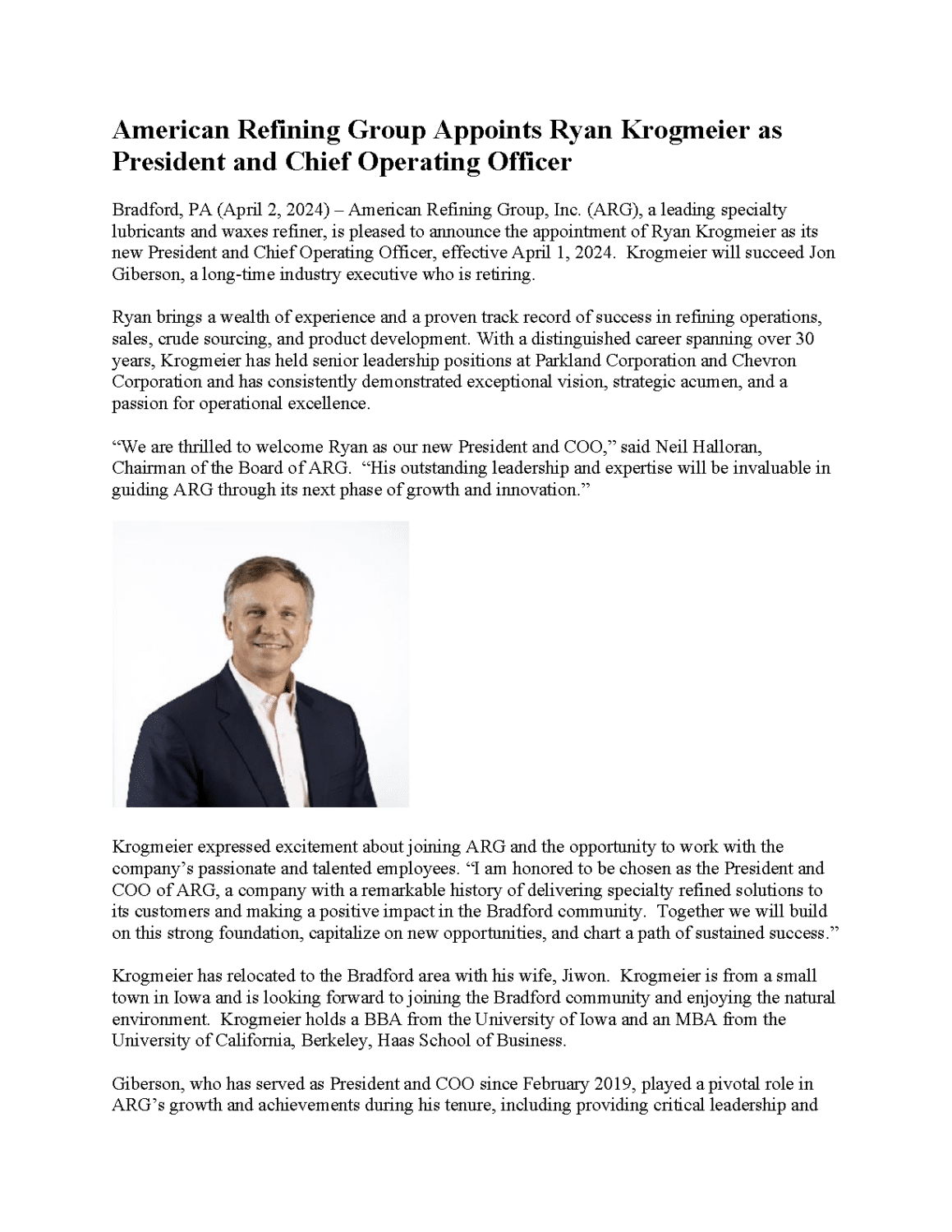

Seen in the photo are (from left) ARG President and COO Jon Giberson, ARG Board of Directors Chairman Neil Halloran and Halloran Philanthropies Executive Director Brian Halloran.

BRADFORD, Pa. – American Refining Group Inc. (ARG) announced this week the expansion of its hydrotreated base oil product offerings.

ARG President and Chief Operating Officer Jon Giberson said, “We are pleased to introduce a selection of new hydrotreated base oils with improved color, oxidative stability, and reduced sulfur content.”

ARG’s line of new hydrotreated base oils includes Kendex® 0070, 0100, 200H, 250H, 300H, 325H, 500H and 600H.

Giberson said, “American Refining Group stands for unrivaled quality in refined products. From our reliable ARGold Legacy™ and the well-received ARGold™ bright stocks, to Kendex® 0060HT and 0150H, these new hydrotreated base oils add still more versatility to the ARG product line that our customers rely on and trust.”

Giberson added that the new hydrotreated base oils may be of particular interest to blenders of industrial lubricants such as process oils, hydraulic and gear oils, as well as elastomer, rubber and plasticizer applications.

Made in Pennsylvania, ARG’s products are regionally sourced and widely distributed to various industries. To learn more, visit www.amref.com/products/ and reach out to an ARG salesperson with any questions via the product inquiry form.

Established in 1881, ARG’s unique facility is situated on approximately 131 acres in Bradford, Pennsylvania, the heart of McKean County and the birthplace of the U.S. domestic oil industry more than 100 years ago. The refinery has a rated capacity of 11,000 barrels per day and processes light, sweet, paraffinic crude. This type of crude is available domestically, and ARG purchases most of its crude from sources in Pennsylvania, Ohio, New York and West Virginia.

ARG feedstocks are converted into high-quality waxes, lubricant base oils, gasoline and fuels, as well as a wide variety of specialty products. American Refining Group’s state-of-the-art blending and packaging facilities produce a full spectrum of finished lubricants. These products are available in a broad range of package sizes, including bulk, and can be delivered by rail or truck. The facility’s commitment to quality is proven through its packaging plant and refinery’s certifications to ISO 9001:2015 and Made in USA standards.

For more information about ARG, visit www.amref.com or follow the refinery on social media.

–30–

“Giving is not just about making a donation. It is about making a difference.” – Kathy Calvin

VILLANOVA, Pa. – American Refining Group Inc. (ARG) Chief Executive Officer and Board Chairman Harry Halloran Jr. passed away Dec. 18 at home, surrounded by his family.

“My father lived an extraordinary life,” his son, Neil Halloran, said. “He was a businessperson, a philanthropist, a husband and a father. He was a big thinker and a kind soul. He pursued so many interests, launched so many ventures and impacted so many lives.”

Harry purchased the historic Bradford facility from Witco in 1997 when, after acquisition by Sun Oil Co., the refinery had lost its brand.

“In Pursuit of the Greater Good: Community, Continuity and the ARG Refinery,” the book that recounts that fateful story, quotes Harry, “It was very exciting to walk through this complex refinery – twenty times more complex than anything I had seen in all my years in the transmix business.

“From that first visit,” he recalled, “we had a gut sense about the people we met, the town of Bradford, and the need to keep this small refinery alive.”

In 2017, when ARG marked 20 years’ ownership of the Bradford refinery, the company renamed a private road for Harry. Formerly Brad Penn Way, the road running in front of ARG’s Main Office and Research & Development buildings just off North Kendall Avenue in the city of Bradford is now known as Halloran Way.

ARG President and Chief Operating Officer Jon Giberson said, “It’s the Halloran Way – not only the way ARG’s refinery does business, but also the road that runs through it. The designation recognized Harry’s commitment to ARG, its employees, all of its partners and the community.”

The refinery, established in 1881, will mark its 25th anniversary as ARG in 2022.

“Anyone who shared time with my father – even a short interaction – probably witnessed his extraordinary positivity,” Neil said. “His capacity to see a bright future during the most trying of times allowed him to see the potential in this refinery when he purchased it 24 years ago, and to push forward during the years when so many predicted it would be shut down.”

Effective immediately, Neil assumes leadership as ARG Chairman of the Board. Neil explained the plan for him to gradually take on this role has been in place for some time. When Harry suffered a stroke four years ago, Neil was named lead director and he began working closely with Harry and the ARG leadership team.

Neil said, “It is the aim of the Halloran family, the board and the leadership team to maintain continuity in the company’s management.

“Despite the difficulties of these past years, Dad was able to pass on knowing that ‘the little refinery that could’ was stronger than ever and pushing ahead at full steam.”

Harry was a dedicated philanthropist and, in that spirit, ARG encourages its employees’ community involvement, generosity and volunteerism. Brian Fernandes-Halloran, another of Harry’s four sons (Mark and Kevin), is executive director of Halloran Philanthropies, established to promote human wellbeing and to create “The World We All Want.”

Corporately, ARG donates thousands of dollars annually, and thousands more are contributed through its employee-donation-matching program to other local non-profit organizations and relief efforts. The matching-gifts program allows for any donation made to a 501(c)(3) organization to be matched, dollar for dollar (up to $500 per request, per year), by the company.

ARG focuses its charitable giving on education, economic development, human services and health care. The company advances its community development efforts through a commitment to keeping its dollars local and to giving back at every feasible opportunity.

The company employs more than 350 people in its Ohio, Bradford and Pittsburgh offices and maintains relationships with local contractors and providers of other goods and services. The refinery acquires more than 3 million barrels of light, sweet, paraffinic crude oil annually, the majority of which comes from suppliers in Pennsylvania, New York and Ohio.

ARG’s was the first refinery to achieve Made in USA certification, having successfully completed the rigorous, third-party supply chain audit to verify compliance with strict standards. ARG proudly bears these trust marks today as an integral part of its heritage and its future.

Harry’s full obituary will be shared when available.

For more information about ARG, visit www.amref.com or follow the refinery on Facebook and LinkedIn.

–30–

Media contact:

Sara Furlong

Executive Communications Coordinator

We’re proud to be featured in the Pennsylvania Chamber of Business and Industry’s Business Spotlight in its Spring 2021 edition of Catalyst Magazine! Click below to have a look:

As seen in the May 14, 2021, edition of ILMA Week: