Step 1: Become an approved contractor – Requirements to work at ARG’s Refinery.

- Complete the Contractor Pre-Qualification Form (SAFE 60 PQF)

This includes supplying Workers Compensation EMR information and OSHA logs.

Click here to view the Contractor Pre-Qualification Form.

- Complete the Subcontractor approval form (SAFE 60SCF)

This is only required if a subcontractor is used.

Click here to view the Request for Subcontractors Form.

- Supply all required insurance

Your certificate needs to include the following endorsements:

- ARG is listed as Additional Insured for General Liability Policy

- ARG is listed as Additional Insured for Automobile Policy

- Waiver of Subrogation for General Liability Policy

- Waiver of Subrogation for Auto Policy

- Waiver of Subrogation for Workers Compensation

- 30 Day notice of cancellation

View General Conditions here.

- Review ARG's General Safety Standard (SAFE 69)

Click here to view ARG's General Safety Standard.

- Complete the 4-Gas Meter Acknowledgement Form

Click here to view the 4-Gas Meter Acknowledgement form.

- Complete the QA-331 Supplier Profile Questionnaire

Click here to view the QA-331 Supplier Profile Questionnaire.

- Review ARG’s Confined Space Rescue requirements and acknowledge.

Click here to view ARG's Confined Space Rescue Requirements.

- Supply all requested certifications, qualifications, and/or documentation requested by the Health & Safety department.

After reviewing the necessary documentation, you might need to submit additional training certifications or qualifications, along with policies, procedures, and so on.

- All required information must be submitted to our Purchasing Department.

• Amy O'Neil – aoneil@amref.com

• Kortney Regis – kregis@amref.com

Step 2: Requirement prior to arrival

- Contractor orientation

- Ensure all individuals coming onsite to perform work have completed ARG’s Contractor Safety Orientation.

- Link: www.argexams.com

- All individuals are required to create a username/password, enter their full name/company, and complete the orientation prior to arriving onsite.

- Upon completion of your orientation, you’ll be presented a certificate or completion with your name and company, ensure you take a screenshot or print your certificate.

- This orientation is valid for 1 year and must be renewed annually.

- Ensure all individuals coming onsite to perform work have completed ARG’s Contractor Safety Orientation.

Step 3: Important information to know prior to working onsite at ARG

- Facial Hair Policy

- All contractors that are performing work within ARG’s refinery must follow the acceptable facial hair requirements.

- Clean-shaven or mustaches that don’t extend past the corner of the mouth.

- The only exceptions to this policy are:

- Truck drivers/delivery personnel

- Utility company personnel

- Visitors or Contractors conducting a walk-through or bidding a job.

- Cleaning personnel

- Railroad personnel

- All contractors that are performing work within ARG’s refinery must follow the acceptable facial hair requirements.

- Smoking Policy

- ARG is a smoke and vapor free workplace. Smoking and/or vaping is on ARG property, inside vehicles or any ARG buildings is strictly prohibited.

- Designated smoking areas are located:

- Kendall Ave – outside the main gate by Kendall Ave.

- Mill Street – on the fence line outside the Boiler House gate

- Hilton Street – in the Millwright parking area.

- Packaging Plant – Creekside across from the plant.

- Foster Brook Area – across from the gate on Bolivar Drive

- Drug/Alcohol Policy

- Illegal drugs and possession of alcohol are prohibited on ARG property. All individuals are subject to search while on company property.

- Vehicle Restriction

- ARG is committed to minimizing vehicle traffic within the refinery. Contractor vehicles will only be permitted within the refinery if the vehicle is necessary to complete their job. Also, there will be a 1 vehicle limit, not including necessary heavy equipment (examples: vac trucks, JLG’s, cranes, etc.)

- All personnel operating a vehicle must have a valid driver's license.

- Plant PPE

- ARG’s required plant PPE includes the following:

- Hard Hat

- Steel or Composite toe boots

- FRC clothing (NFPA 2112)

- Safety glasses or prescription safety glasses with side shields.

- Personal 4-gas monitor

- Hearing protection

- NOTE: Based on the job task being performed, additional PPE will be required. ARG is not responsible for providing the upgraded PPE, this is the responsibility of the contractor.

- ARG’s required plant PPE includes the following:

- Cell Phones

Cell phone use is restricted to the control rooms or in a parked vehicle. No cell phone use is permitted within the process units or while driving a vehicle.

- ARG’s Life Saving Rules

ARG has established 10 life saving rules to protect and prevent serious injuries and fatalities. These life saving rules must be followed while working onsite. Willful violations of these life saving rules may result in removal from the facility.

- Safe Work Permitting

All work must be conducted under a valid Safe Work Permit obtained by the owning department. The Safe Work permit serves as a life saving tool to ensure all required permits are recognized, hazards are identified, and protective measures for mitigation are in place.

- Energy Isolation (LOTO/Line Break)

All work requiring energy isolation must be properly isolated from all energy sources, purged, depressurized, and verified prior to beginning work. Energy isolation serves as a life saving tool by ensuring all energy sources are isolated and verified prior to beginning work.

- Confined Space

All work within a confined space must follow our Confined Space pre-entry, entry, and permit requirements to ensure the space is safe to enter and work can be performed safely. Confined Space safety requirements ensure proper authorization is given prior to entering the space.

- Hot Works

All work activities that have the potential to produce heat from flame, sparks or other sources of ignition with sufficient energy to ignite combustible materials or explosive atmospheres must follow our Hot work standard. Hot Work safety requirements ensure all ignition sources and flammable materials are controlled, as well as proper authorization, prior to beginning Hot Work activities.

- Excavation

All work activities that require excavating or trenching must have proper pre-planning conducted, proper site evaluations, and proper protective systems, as well as follow all other requirements in our Excavation/ Trenching standard. Excavation safety requirements ensure all precautions are addressed and proper authorization prior to beginning any excavation/trenching work.

- Working at Heights

All work activities that require work at heights must follow our working at heights standard. Working at heights requirements ensure all fall hazards are understood, hazards and risks are mitigated, and work is conducted in a safe manner while complying with applicable regulations.

- Lifting Operations

All work that requires any variation of rigging and/or lifting must comply with our safe lifting/rigging standards. Safe Lifting operation requirements ensure the right equipment is selected and used for the job, the job is properly planned to consider and mitigate risks, all access to the lifting zone are barricaded, and no load limits are exceeded.

- Electrical Safety

All work that requires low and/or high energy electrical work must comply with our electrical work standards. Electrical safety requirements ensure awareness of electrical hazards, risk involving electric, preventative measures, and proper equipment/PPE to perform the job.

- Management of Change

All work that requires a change to new and/or existing processes, equipment, chemicals, technology, tanks, procedures, etc. must comply with our management of change standard. MOC requirements ensure that changes within the organization are properly tracked, managed, and communicated to affected employees and/or contractors.

- Disabling Safety Equipment

All work that requires safety critical equipment to be bypassed, disabled or removed from service for any length of time must comply with our deficency management program. Disabling safety equipment requirements ensure the stated equipment to be disabled has to be, the risks involved, justification for continued operation, additional safety precautions in place, and the action item that will correct the deficiency.

- JSA’s (click and has a drop-down box)

- ARG requires a JSA to be completed daily for all job tasks. This JSA must be completed in the field during the joint jobsite visit.

- All contractors are required to use ARG’s JSA form:

- Link:

Step 4: Requirements upon arrival

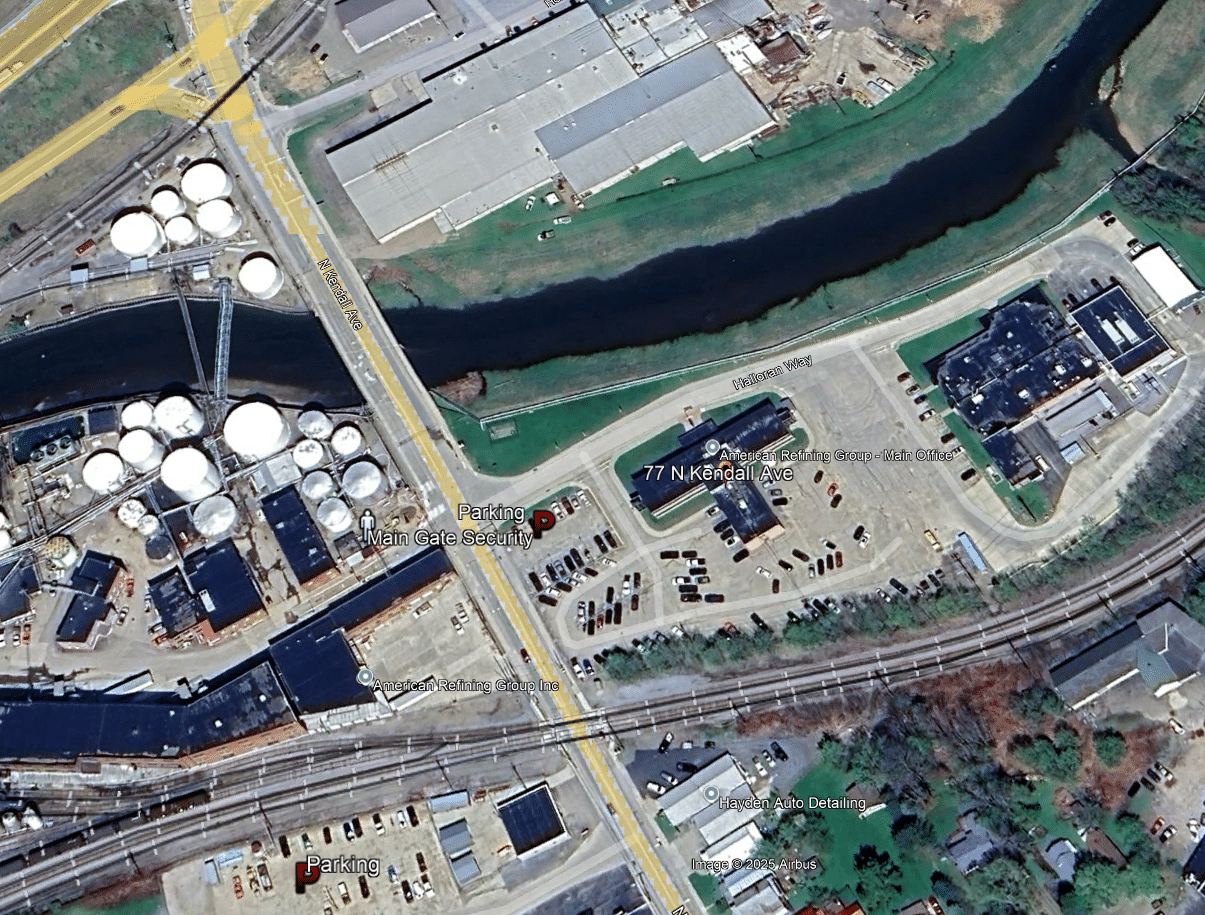

- Parking

When arriving onsite contractor and visitor parking in located in the small lot just off North Kendall Ave. or in the Conley Parking lot.

- Check-in location

All contractors and/or visitors must check-in with the weighmasters at the Watchblock.

- Badge/Access Control

All individuals will receive a personalized visitor or contractor badge. The process will go as follows:

- The weighmaster on shift will verify the individual checking in has completed their contractor safety orientation. If this hasn’t been completed or is expired, they will ask you to leave and complete the orientation.

- Once the orientation is verified, they will add your full name and contractor company name to a badge. You must then swipe this badge on the IN reader inside the Watchblock.

- This badge must be kept on your person at all times.

- You are required to swipe this badge on the IN-access reader when you enter a process area, and on the OUT-access reader when you exit a process area.

- The badges must be returned at the end of each day.

- Vehicle Pass

- As mentioned earlier in the process, ARG is committed to minimizing vehicle access. A vehicle pass will be issued upon the completion and approval of the vehicle request form.

- If the vehicle is approved the vehicle pass must be displayed at all times from the rear-view mirror, and the ARG Contractor Flag must also be displayed on the outside of the vehicle.

- The vehicle passes and the ARG Contractor Flags must be returned at the end of each day.

Contact information:

Michael Salada – H&S Specialist I

Email: msalada@amref.com

Phone: 814-368-1201

Sabina Vecellio – H&S Specialist II

Email: svecellio@amref.com

Phone: 814-368-8740

Tyler Smith – Director, Health & Safety

Email: tsmith@amref.com

Phone: 814-368-1330

Amy O’Neil – Procurement Manager

Email: aoneil@amref.com

Phone: 814-368-1278

Kortney Regis – Procurement Specialist

Email: kregis@amref.com

Phone: 814-368-8754